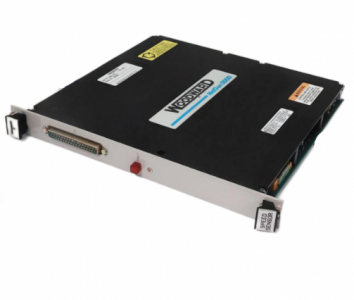

WOODWARD 5464-414 Analog Input/Output Combination Module

This model is a very crucial general-purpose analog input/output module in the Woodward MicroNet and NetCon control systems.

1. Product Description

The Woodward 5464-414 is a standard analog I/O module. It is specifically designed for the MicroNet digital control system and is used for monitoring and controlling prime movers (such as gas turbines, steam turbines, and large engines).

This module, through its high-density channel design, can simultaneously handle multiple analog signals and serves as the core interface between the system and on-site sensors and actuators.

2. Technical Data Sheet

Model: 5464-414

Series: MicroNet / NetCon 500

Input Channels (Inputs): * Usually consist of 8 analog inputs.

Supports 4–20 mA current signal or 0–5 V / 0–10 V voltage signal.

Output Channels (Outputs): * Usually consists of 4 analog outputs.

Mainly used for 4-20 mA proportional control.

Accuracy: 0.1% of full scale (typical value).

Isolation: The module has current isolation between the channel and the bus, preventing external electromagnetic interference (EMI) from affecting the control system motherboard.

Operating Temperature: -40 °C to +70 °C.

Power Consumption: Approximately 5 – 10 W.

5464-414

3. Related Models / Components

The model 3464-414 is usually used in conjunction with the following Woodward hardware:

5466-316 / 5466-1035: MicroNet CPU main processing module.

5464-834: Analog Input Terminal Block (FTM – Field Terminal Module).

9907-014: Special shielded cable for connecting the module to the terminal block.

5464-544: Discrete (Discrete) I/O module.

4. Application Cases (Application Examples)

Gas Turbine Control: This is used to collect exhaust temperature and fuel pressure signals, and to output signals to control the fuel regulating valve.

Steam Turbine Governing: Monitors the rotational speed of the steam turbine (in conjunction with the speed module) and the inlet steam pressure, and drives the servo actuator.

Compressor Anti-Surge Control: Real-time collection of pressure and flow transmitter data to ensure the compressor operates within a safe range.

Grid connection of the generator set: Processing power measurement signals and voltage regulation instructions.

5. Product Advantages and Features

High Reliability: Specifically designed for industrial mission-critical applications, with an extremely long Mean Time Between Failures (MTBF).

High-density design: Integrating input and output functions within a single slot, saving space in the control cabinet.

Hot-swappable support: In a redundant system configuration, it is supported to replace modules while the system is powered on without affecting its operation.

Powerful self-diagnosis function: The module can automatically detect loop breakage, short circuit or hardware faults, and report the error code to the main controller.

Resistant to environmental interference: Conformal coating can operate stably in high humidity and high salt spray environments.

6. Other Models in the Series

The Woodward MicroNet I/O series also includes:

5464-211: Special RTD (Resistance Temperature Detector) input module.

5464-643: Specialized thermocouple input module.

5464-658: High-speed counter/velocity sensor module.

5466-409: Discrete I/O Combination Module.