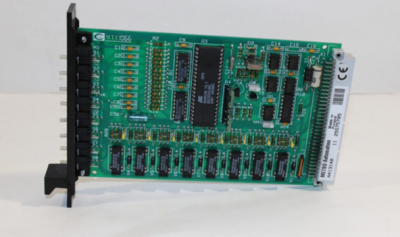

METSO A413140 Controller board

The Metso (now Neles/Valmet) A413140 is a critical electronic component, specifically the Main Circuit Board (CPU/Communication Board) designed for the Neles ND9000 series intelligent valve positioners.

It acts as the “brain” of the device, processing control signals and managing the valve’s advanced diagnostics.

1. Product Description

The A413140 is the primary internal controller board for the ND9000 digital positioner.

It is responsible for receiving the 4-20 mA input signal (often with HART communication), calculating the required valve position, and controlling the pneumatic pilot valves to move the actuator.

This board is engineered to perform high-speed calculations for PID control loops and stores historical data for “Valve Performance Monitoring” and predictive maintenance.

A413140

2. Technical Parameters

| Parameter | Specification |

| Component Type | Main Processing Board (PCBA) |

| Communication Protocol | HART (Typically 4-20 mA loop powered) |

| Input Signal | 4 – 20 mA DC |

| Supply Voltage | Loop-powered (Minimum 9.0 V DC at 20 mA) |

| Microprocessor | High-performance 16/32-bit RISC processor |

| Diagnostics | Online & Offline (Triton/ValvGuard compatible) |

| Mounting | Internal bracket within ND9100/ND9200 housing |

| Protection | Conformal coating for humidity and chemical resistance |

3. Product Advantages & Features

Advanced Control Algorithms: Utilizes proprietary Metso algorithms to eliminate “overshoot” and “hunting,” even in high-friction valves.

HART Integration: Supports full HART communication, allowing technicians to calibrate and troubleshoot the valve remotely using a handheld communicator or PC software.

Performance Diagnostics: Automatically tracks travel distance, number of cycles, and deviation trends to predict when the valve requires service.

Modular Architecture: The A413140 is designed for easy swap-out maintenance, allowing users to upgrade or repair a positioner without removing it from the pipeline.

Environmental Hardening: Built to withstand extreme industrial vibrations and temperatures from -40°C to +85°C.

4. Application Cases

Smart Automation Systems: Integrated into DCS (Distributed Control Systems) via HART for real-time valve status monitoring.

Critical Control Loops: Used in pressure or flow control loops where high-speed response and zero steady-state error are required.

Predictive Maintenance Programs: Used in large-scale plants (Refineries, Power Plants) to identify “stick-slip” or air leaks before a failure occurs.

Safety Instrumented Systems (SIS): Often found in ValvGuard versions of the ND9000 for Partial Stroke Testing (PST).

5. Related & Other Models in the Series

The A413140 is the heart of the ND9000 family, which includes several specialized variants:

ND9100: Universal positioner for rotary and linear valves (Standard HART).

ND9200: High-flow version for large actuators.

ND9300 / ND9400: Versions supporting Foundation Fieldbus or Profibus PA (these use different circuit boards, e.g., A413145).

A413111: The potentiometer (feedback) unit that plugs into this main board.

A413120: The Pneumatic Relay/Pre-amplifier module controlled by this board.