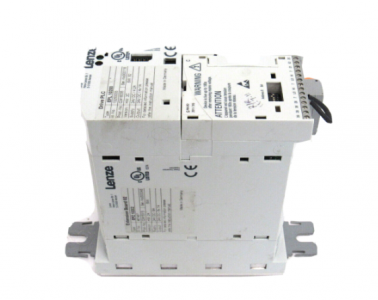

Lenze EPL10200 High-function drive PLC unit

a high-functionality Drive PLC unit commonly used in the Lenze Global Drive 8200 vector and 9300 servo systems.

1. Product Description

The EPL-10200-XX (often referred to as the Drive PLC) is a compact, decentralized control unit that combines the features of a high-performance PLC with direct drive-bus integration.

It allows for complex logic and motion control to be executed locally at the drive level, reducing the load on a central PLC and minimizing communication latency.

Core Function: Decentralized automation and coordinated motion control.

Design: Compact, panel-mounted module designed to snap into drive expansion slots or act as a standalone coordinating unit.

2. Technical Parameters

The “XX” suffix indicates the hardware version or firmware revision (e.g., V6.5. V8.2).

| Parameter | Specification |

| Supply Voltage | 18 – 30 V DC (Typical 24 V DC) |

| Current Consumption | ~200 mA (at 24 V, without external loads) |

| Processor Speed | Bit operation approx. 1.0 µs |

| Program Memory | ~191 kB (ROM) |

| Data Memory | ~25 kB (RAM) |

| Digital I/O | 8 Digital Inputs / 4 Digital Outputs (1 A max) |

| Analog I/O | 3 Analog Inputs (±10 V) / 1 Analog Output (±10 V / ±20 mA) |

| Communication | Integrated System Bus (CAN), support for Profibus/DeviceNet modules |

| Programming | IEC 61131-3 (LD, FBD, ST, SFC, IL) via Drive PLC Developer Studio |

3. Key Advantages & Features

Drive-Integrated Logic: Executes motion-specific logic (like winding, positioning, or synchronizing) directly, ensuring real-time response.

Reduced Wiring: By using the integrated system bus (CAN), it reduces the need for extensive control cabling between the PLC and multiple inverters.

Versatile I/O: Equipped with both digital and analog interfaces, allowing it to process sensor signals locally.

Modular Expansion: Can be expanded with EPZ-10xxx extension boards for additional high-speed counters or extra I/O.

High Precision: Offers rapid response times (under 1 ms in certain configurations) for critical industrial processes.

EPL10200

4. Application Cases

Winding/Unwinding Systems: Precise dancer control and tension regulation in textile or paper processing.

Packaging Machinery: Coordinating multi-axis synchronization and electronic cam profiling.

Material Handling: Managing complex sorting logic and conveyor speeds in automated warehouses.

Labeling Machines: Utilizing high-speed interrupt inputs for precise product detection and label placement.

5. Related Models & Series

The EPL-10200 is part of the Global Drive PLC family. Depending on your needs, you might encounter these related components:

Extension Boards:

EPZ-10201: Standard I/O extension.

EPZ-10203: High-speed counter and specialized technology module.

Alternative PLC Modules:

EPL-10201-XX: A similar variant often found in specific regional or hardware configurations.

Compatible Inverters:

8200 Vector Series: Standard frequency inverters.

9300 Servo Series: High-end motion control drives.

Software:

GDC (Global Drive Control): For parameter setting.

Drive PLC Developer Studio: For IEC 61131-3 logic programming.