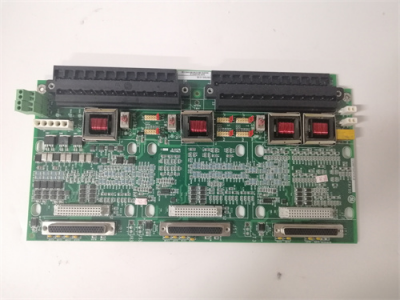

IS200TSVCH1ADC S1CX01H Servo valve interface terminal board

GE IS200TSVCH1ADC S1CX01H is the servo valve interface terminal board (TSVC) of the Mark VIe Speedtronic system.

It is used for analog signal conditioning and electrical isolation of steam turbine servo valves (such as fuel/gas regulating valves), and is compatible with signal conversion and safety interfaces of servo control circuits.

Ensure the precise drive of the executive body and the anti-interference capability of the system. The following are the core information and technical details:

I. Core Positioning and Basic Attributes

Project parameters

Model IS200TSVCH1ADC S1CX01H (S1CX01H is batch/version code)

Brand GE Vernova (formerly GE Gas Power)

Series Mark VIe Speedtronic

Type Servo Valve Terminal Board (TSVC, servo Valve Terminal Board)

Compatible module IS200TSVOH1 (servo control card), UCSC/UCSB controller

The core functions include servo valve analog command output, position feedback collection, signal isolation and conditioning

Isolation grade: 2500V AC electrical isolation between channels and on the system side

Typical applications include fuel valves for gas/steam turbines, servo control of guide vanes, and drive circuits for actuators

Ii. Key Technical Specifications

Signal interface

Output: 4-20mA analog command (driving the proportional coil of the servo valve), 16-bit resolution, accuracy ±0.1%.

Input: 2 channels of position feedback (LVDT/RVDT, supporting sine wave/DC signals), compatible with ±10V/4-20mA feedback signals.

Auxiliary I/O: 2 digital diagnostic inputs (for servo valve status monitoring), 1 fault alarm output.

Electrical Engineering and Diagnosis

Power supply: 24V DC (±10%), power consumption approximately 5W.

Filtering: Built-in adjustable digital filter (0.1-10s constant) to suppress high-frequency interference and enhance signal stability.

Self-diagnosis:

Supports detection of disconnection, short circuit, over-range and abnormal feedback. Fault information is uploaded to the controller through the backplane bus.

Physics and Environment

Installation: Mark VIe standard rack slot, backplane connector communication and power supply.

Operating temperature: 0℃ to 60℃, humidity: 5% to 95%, no condensation.

Size: Compatible with the standard Mark VIe I/O module size, with a weight of approximately 0.8kg.

Iii. Core Functions and Applications

IS200TSVCH1ADC

Signal conditioning:

Convert the digital instructions of the controller into 4-20mA analog signals recognizable by the servo valve, and simultaneously collect the LVDT/RVDT feedback of the valve position to form a closed-loop control.

Safety isolation:

2500V AC isolation design to prevent on-site surges/overvoltage from damaging the control system, suitable for industrial strong interference environments.

Fault monitoring:

Real-time diagnosis of abnormal signal circuits, triggering safety interlocks (such as valve position jamming alarm, command/feedback deviation exceeding limit shutdown), ensuring the safe operation of the steam turbine.

Applicable scenarios:

Widely used in servo actuator circuits such as combined cycle power generation, fuel regulation of industrial drive steam turbines, intake guide vane control, and bypass valve regulation.

Iv. Selection and Supporting Tips

Module pairing:

It needs to be used in combination with the IS200TSVOH1 servo control card, and the instruction issuance and feedback upload are achieved through the backplane bus.

Redundant configuration:

In a dual-machine/TMR system, the corresponding number of TSVC terminal boards and servo control cards should be configured according to the redundant architecture.

Signal matching:

Select the corresponding wiring method based on the type of servo valve (proportional valve/servo valve) and feedback sensor (LVDT/RVDT) to avoid signal mismatch.

V. Core Advantages

High isolation:

2500V AC electrical isolation ensures electrical safety between the control side and the field side, enhancing anti-interference capability.

High precision:

16-bit signal conversion + adjustable filtering ensures precise positioning of the servo valve, meeting the high-precision control requirements such as fuel regulation of steam turbines.

Easy to maintain:

Modular design, supports hot plugging (for some configurations), clear fault diagnosis, facilitating quick location and replacement.