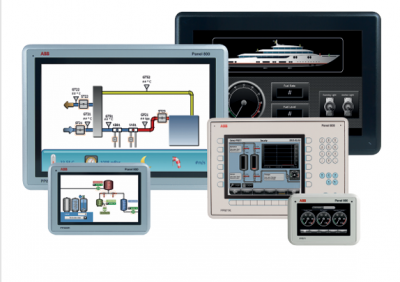

Panel 800 version 6 ABB

A wide range of user-friendly, intuitive and ergonomic operator panels

for process automation systems gives you the right information

at the right time, in the right place.

Panel 800 Version 6

Panel 800 family comprises of user-friendly,

intuitive and ergonomic operator panels that

combine slim, space-saving dimensions with

a comprehensive range of advanced functions.

Adding to the already well established feature

rich Panel 800 version 6 our new Rugged and

Black panels are designed to perform in chal

lenging harsh environments. Whether it is heavy

outdoor use, usage in areas with explosion risk,

or ship bridge use in marine applications, they

are ready to provide you with the information

needed.

Designed to make process automation easy, all

panels are equipped with advanced functionality

for process and equipment control, maneuvered

either by function keys located next to the screen

or by touching the LCD display. Combined with

market-leading performance and stunning

graphical ability, Panel 800 erodes the line between

ordinary Operator Panels and PC-based HMIs.

Panels are configured using ABB’s Panel Builder

tool that contains a wide range of advanced

functions. The functions are tested and developed

with customer needs and preferences in focus

Key benefits

• Easy to use

A fully deployable HMI with comprehensive

and integrated templates and libraries for every

conceivable process. The Panel Builder tool,

with familiar Microsoft® Windows® environment

along with multiple language support results in

remarkably quick, easy and efficient engineering.

• State-of-the-arts graphics

Vector-based, high-resolution graphics in

TFL/LED display, with icon-based interface,

navigation and control.

• Robust and reliable

Panel 800 is constructed in a strong yet

lightweight diecast, powder-coated aluminum

housing. IP65/IP66 front casing withstands wet,

dusty and demanding environments. Operating

temperatures ranging between -30 o C to 70 o C

with maximum 85% humidity.

• Truly open platform

Built on open architecture and technologies

that accompany the . NET framework, these

panels are capable of multi-brand controller

connectivity. A multitude of connection options

are available for local communication, expansion,

remote access and more.

• Try your application before you use it

Nice possibility to simulate and run the appli-

cation directly from the Panel Builder 800

before you use it.

Panel 800 as main / secondary HMI

Variable speed drive/

motor controller etc.

Panel 800 as Gateway

The Panel 800 range is the perfect fit to act as

the main HMI for smaller automation systems,

or as a secondary complimentary HMI for

mid-sized or larger systems. A standard panel

is suitable to handle process information from

up to 1000 signals. High performance panels can

handle up to 2000 signals.

Many process sites has multiple brands of

PLCs, and often these PLCs need to be able

to share data and communicate with each other.

Thanks due to the wide range of supported

communication protocols, Panel 800 can act as

gateways between PLCs from different vendors.

Panel 800 as local / field HMI

Panel 800 runtime

Using Panel 800 Runtime and dedicated license

dongles, Panel 800 applications can be run on

normal Windows PC. This enables engineering

efficient reuse of the panels applications in

situations when a PC based HMI is required

in addition to process panels. Since Panel 800

Runtime can be used to visualize data from up

to 4000 signals, it is also suitable for mid-sized

SCADA applications even when process panels

are not needed.

Panel 800 are industrial grade process panels

and are well suited to be located in the field.

Using the extra rugged panels the HMI can be

brought even closer to the process