GE Hydran M2-X is an intelligent online monitoring system

GE Hydran M2-X is an intelligent online monitoring system

Hydran M2-X is an intelligent online monitoring system that can measure the content of flammable gas and moisture in dielectric oil, used to assess hazardous conditions, foaming temperature and aging rate, as well as early detection of initial faulty equipment in transformers (or any other oil-filled electrical devices).

Gas detection

The sensor of Hydran M2-X is equipped with a gas detector, which is a pair of

Four gases are the main indicators of initial faults in oil-filled electrical equipment

Equipment

Hydrogen (H

• Carbon monoxide (CO

• Ethylene (C

• Acetylene (C

Note: The gas detector measures the comprehensive value of the above-mentioned dissolved gases

In oil

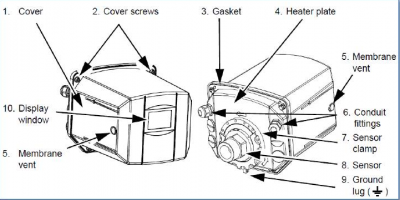

The housing is composed of the following parts: 1. Cover: The cover is for mechanical and weather protection sensors and electronic cages (see Figure 2-4). 2. Lid screws: Four screws secure the lid in place. The cover can be easily removed to enter the electronic card holder. 3. Gasket: This gasket ensures that the connection between the cover plate and the heating plate is waterproof. 4. Heating plate: The heating plate can accommodate dynamic oil sampling. The dynamic oil sampling system is carefully controlled to generate oil convection and ensure accurate gas readings

The sensor continuously performs three measurements: • Gas level: The gas detection is based on the flammable gas dissolved in the oil entering the electrochemical gas detector (located inside the sensor) through a selective breathable membrane. The gas detector, where gas combines with oxygen (from ambient air), is measured by an electronic circuit and converted into per minute. The gas detector is sensitive to the main gases. The initial fault indicators of oil-filled electrical equipment: – hydrogen (H) – carbon monoxide (CO) – ethylene (C) – acetylene (C) • Moisture content: Moisture detection is carried out by a film capacitor moisture sensor. The capacitance value of this sensor is determined by the moisture content. This value is converted into an electrical signal, that is, digitized for the CPU to read.

Sensor temperature

For the recommended operating temperature range of the sensor, please refer to

Technical specifications in Appendix A. The sensor temperature is

Dynamic oil sampling system for heating plates. External

The factors influencing the temperature of the sensor include:

• Ambient air temperature around Hydran M2-X.

The oil temperature behind the valve for installing Hydran M2-X

Please note: When the sensor temperature

Exceed the limit. For more information, please refer to Sections 3.3.2.6 and 6.3.

Heating plate (Dynamic oil sampling system)

The dynamic oil sampling (DOS) system uses controlled heating and passive

Cool to stimulate the oil movement in front of the sensor to ensure representativeness

The sample is always supplied to the sensor.

Heating is achieved by using a heating resistor installed on the inner side

Heating plate. The heating power is controlled by a time ratio algorithm.

This algorithm adjusts the temperature near the required set point.

Please note: If an open circuit of the thermistor is detected, the heating power supply will be turned off.

Note: The temperature limit for the dynamic oil sampling system is 50°C (122°F). One

The thermal fuse with a rated value of 80°C (176°F) is located on the base plate, and the FUI is located

Provide protection on the power board to prevent any faulty circuits from the control