ABB What are the general scenarios of AC800PEC?

ABB What are the general scenarios of AC800PEC?

Chemical applications: • OLTC step compensation for smooth process control- IDC current step compensation for smooth current change when stepping up • Power factor compensation by OLTC • Predictive maintenance features can be included • Software protection packages including:- DC over current protection- AC over- and undervoltage protection- AC phase unbalance protection- System unbalance protection for 12 pulse systems • DC earth fault detection available by 3 voltmeter method • Process pulse block loop with SIL 3 level • Voltage ride-through in case of incoming voltage dips

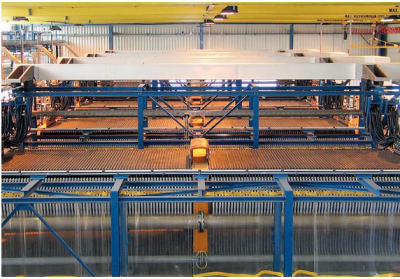

Electrowinning industries (copper & zinc): • IDC current step compensation for smooth current change when stepping up • Power factor compensation by OLTC • Predictive maintenance features can be included • DC overcurrent protection • AC over- and undervoltage protection • AC phase unbalance protection • System unbalance protection for 12 pulse systems • Master DC current control for parallel rectifier units • DC open loop detection during start-up • DC open loop protection during operation

DC power supplies for graphite electrode plants The graphitisation process demands a large variation of voltage and current from the DC power supply. • Constant DC power suppy for the process irrespective of changing process resistance – Possible due to the very fast cycle times of AC 800PEC controller. • Customer tailed process recipes can be added and modified from the operator panel in order to meet the specific customer requirements. • After adding the corresponding recipes, the rectifier follows the predefined DC current, DC voltage and maximum allowed power set points, including all necessary graphitisation specific protection functions