Yaskawa H1000 high-performance heavy-duty frequency converter

Yaskawa H1000 high-performance heavy-duty frequency converter

H1000 Heavy-duty high-performance frequency converter

The brand-new Yaskawa “H1000” heavy-duty frequency converter performs stably and outstandingly in the heavy industrial field!

The industry-leading driving performance stems from our confidence in the product.

Advanced motor drive technology brings about efficient operation.

It can play to its strengths according to different uses and is reliable both in performance and control!

“H1000” is presenting itself in an exquisite manner, comprehensively assisting your work.

Features

High output & high performance

Reliable torque limit (when driving induction motors and synchronous motors)

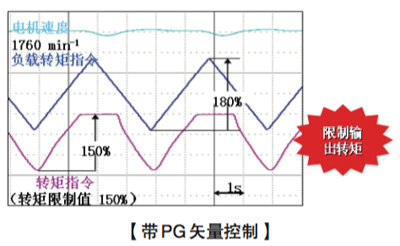

When it is necessary to protect machinery, the high-precision torque limiting function under vector control is used to limit the output torque.

When there are sudden load changes, the machinery is protected by the torque limiting function.

High control accuracy (when driving induction motors and synchronous motors)

High control accuracy enhances mechanical performance.

The new online self-learning and adaptive control methods suppress the impact when the motor temperature rises.

High response and prevention of vibration and overshoot

Both IM motors and PM motors can achieve speed responses above 50Hz. (Occasions with PG control)

In situations where mechanical rigidity is insufficient, a vibration-free and overshoot response can be achieved through acceleration and deceleration compensation (feedforward function). The debugging of the speed controller (ASR) is simple.

Acceleration and deceleration time • S-shaped characteristic switching ensures smooth acceleration and deceleration.

High-precision torque control (when driving induction motors and synchronous motors)

Both IM motors and PM motors can achieve high-precision torque control (±5%). It is acceptable when equipped with PG vector control.

It can achieve fine-tuning of the speed-limiting input mode, speed-priority loop operation, and torque command polarity.

Adaptive control can suppress the rise in motor temperature and the impact during electric/regenerative switching.

Convenience & Environmental Protection

Customize the frequency converter according to your preferences

Equipped with visual programming function DriveWorksEZ *

It is equipped with a USB port for easy connection to a computer

Easy debugging

Automatically set appropriate parameters

Environmental resistance

Environmental resistance design

The standard product complies with the RoHS(European Restriction of the Use of Certain Hazardous Substances) directive

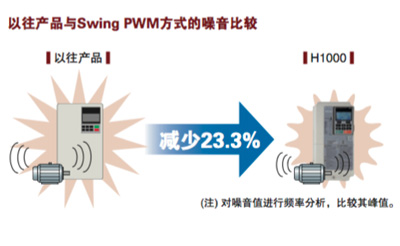

By adopting the Swing PWM mode, it not only suppresses electromagnetic interference but also reduces harsh noise

Suppress the high-order harmonics of the power supply

A variety of communication purchase cards

Standard equipped with RS-422/485 communication function

By installing the communication purchase card, it can be used in various field networks such as PROFIBUS-DP, DeviceNet, CC-Link, CANopen, LONWORKS *, MECHATROLINK-II *, etc

It saves wiring and space, and the mechanical design, installation and maintenance are all convenient

Long-life design

The design life of the frequency converter is 10 years

Due to the absence of copper loss in the rotor and the low bearing temperature of synchronous motors, the lifespan of the motor bearings is approximately twice that of induction motors

By diagnosing and predicting the lifespan, reminder signals for the maintenance time of vulnerable parts can be output

Simple maintenance

Detachable terminal block with parameter backup function

Support tool: DriveWizard Plus*

Parameter copy function

Safety & high reliability

Comply with safety standards

Complies with EN954-1 Cat.3 and IEC/EN61508 SIL2

The EDM(External Device Monitor) function that can monitor the actions of security functions has been added

The braking function is indeed reliable

After using the excitation braking function, emergency braking can be achieved even without a braking resistor

For models with an expanded built-in braking transistor, if a braking resistor is added, greater braking force can be obtained

Safe stop during power outage

It is equipped with the KEB(Kinetic Energy Back-up) function, which enables the motor not to run freely during power failure but to decelerate and stop quickly and safely