The Yaskawa machine controller MP3300 is the successor model of the MP2000 series

The Yaskawa machine controller MP3300 is the successor model of the MP2000 series

It is a machine controller with a very high synchronous scanning speed. By combining with the AC servo Σ-7 series, we provide system solutions for customers’ equipment to meet their usage requirements.

Features

Superior performance

Improvement of control performance

High-speed and high-precision computing and application processing have been achieved, and the program capacity has been expanded. Meanwhile, it can communicate at high speed synchronously with servo and frequency converters that support the open motion network MECHATROLINK-III, which improves the production efficiency and performance of the device.

Supports double-precision real number type and 64-bit integer type data, enabling higher-precision control

It supports double-precision real number type and 64-bit integer type data, which can reduce the approximate value error during operation and thus achieve higher-precision control.

The fastest motion network in the same industry

The MP3300’s mainframe CPU is standard-equipped with the fastest motion network MECHATROLINK-III in the industry, achieving high-speed and high-precision communication through precise motion control.

Up to 16 axes can be controlled

Under the same circuit, the MP3300 can control up to 21 stations (up to 16 axes for servo systems) of motion systems. When expanding the system, a flexible system can also be built by purchasing modules.

More convenient operation

Automatic configuration, automatic setting

Automatically identify the selected modules or servo units and I/O devices connected to the MECHATROLINK of the motion network, and automatically complete the Settings.

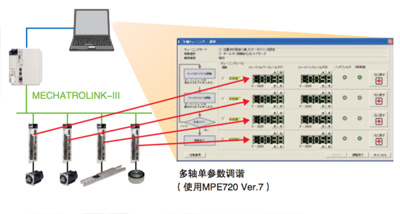

Shorten the servo adjustment time of multiple axes

The parameters of multiple axes can be tuned on one screen without opening the adjustment screens of each axis, which can significantly reduce the adjustment time.

Reduce the burden of building motion control systems using servos

The drive system can be standardized simply by adding a motion system to the existing sequential control system, thus eliminating the need to consider the type of PLC.

It can be connected to the PLC without any program (only Settings required)

Standardization of the drive system can be achieved without relying on the type of PLC.

More environmentally resistant and more eco-friendly

It has excellent performance that can be used in a variety of different environments!

The operating ambient temperature range has been expanded from 0°C to +60° C. (When the temperature exceeds +55°C, a cooling fan needs to be installed inside the cabinet.)

Inheriting the environmental resistance of the MP2000 series

Support the visualization and energy conservation of the motion system

It is equipped with a motion system power monitor connected to the MP3300. Help achieve daily power monitoring and annual power consumption reduction plans.

It helps to reduce the environmental load

Complies with the European REACH standard.

Higher security

Protect the system from the influence of abnormal temperature

The MP3300 and Σ-7 series servo units and servo motors are all equipped with temperature sensors. The temperature status of the product can be directly monitored through sensors, allowing for early detection of abnormal conditions and prevention of malfunctions.

Meanwhile, the temperature status can be monitored at any time, which is reassuring.

It has powerful security features set up to prevent the outflow of experience and technology

It is equipped with a variety of powerful functions to prevent illegal access

Carry out unified security management on a document basis

It can be accessed and managed through a password

More practical

Enhanced practicality and traceability

M can easily handle large volumes of data and effectively utilize the record file transfer function.

It is convenient to load and save project files on site

It can be operated through the toggle switch on the main body of the CPU unit. Even in places where it is impossible to carry a computer, it is easy to upgrade the version and back up the device.

It can read and write register data and supports large-capacity data (using USB flash drives).

Register data can be imported and exported through the new ladder diagram program command. At the same time, it can also perform simple operations on large-capacity data.

The operating status of the device can be saved to the built-in random access memory or a USB flash drive

The operating status of the device (recorded data) can be saved to the USB flash drive connected to the CPU or the built-in random access memory of the CPU unit through the recording function. The data to be saved can be in binary or CSV format.

Grasp the data changes almost without omission

Records can be made during the time period synchronized with the scan, thus enabling the detection of subtle data changes that are usually imperceptible.

It can perform high-speed recording in synchronization with scanning, detect previously undetectable faults, and precisely identify the causes.